Here we would like to inform all of our valued clients, in order to offer a better service, we have a new website www.cnpoultech.com with a wide range of the products we supply. For old website www.poultech.net, it is still available. And we also moved to a new office from the year of 2020, new office address: Building-A, No.197 of Pingan Road, Zhengzhou City, Henan Province, China. All bank details (including company name, address and bank account no.) remain unchanged. For the safety of your transfer, please reconfirm the bank account details as follows: COMPANY(BENEFICIARY) NAME: HENAN POUL TECH MACHINERY CO., LTD. ADD: ROOM NORTHEAST, 14 FLOORS, BUILDIN2-A, NATIONAL UNIVERSITY TECH PARK, CHANGCHUN ROAD, ZHENGZHOU HIGH TECH ZONE, HENAN, CHINA BANK ACCOUNT NO.: 252029571819 SWIFT CODE: BKCHCNBJ530 BANK NAME: BANK OF CHINA ZHONGYUAN SUB-BRANCH ZHENGZHOU CITY BANK ADD: NO.123 ZHONGYUAN ROAD, ZHONGYUAN DISTRICT, ZHENGZHOU CITY, HENAN PROVINCE, CHINA. From the year of 2021, we have an office in Labadi, Accra, Ghana, with our sales manager Mr. Steven Zong, mobile no.: 0596569003. We welcome clients from Ghana contact with Mr. Steven Zong directly for detail proposal and quotation. HENAN POUL TECH MACHINERY CO., LTD. DATE: 08 FEB, 2022

During July 1st – 3rd, 2021, the weather is very hot, but there are some workers from POUL TECH were loading cage equipment under the scorching sun because there will be 21* 40’ HQ containers transport from POUL TECH to Middle East farm project. At the beginning of project, this farm will raise 150000 birds layer and 80000 birds pullet use POUL TECH cage equipment. The farm has finished the construction 3 chicken houses before loading cage, so the customer need delivery cage equipment urgently. In order to customer’s farm finish cage installation and raise chicken on time, POUL TECH decide to loading 21 containers use 3 days on hot weather. Enter the POUL TECH factory, you will see that our workers is loading cage with forklifts. Thanks for our workers hard work and ensure we delivery cage equipment to our customer timely.

Layers have different water requirements in different seasons. According to farmers’ breeding experience, in general, the daily water requirement of each chicken is about 110 ml in winter, 280 ml in summer, and 200 ml in spring and autumn. When the egg production rate increases, the water demand will also increase. Pay special attention to the water supply work, otherwise it will directly affect the egg production and health of the chicken. At 8 am, 12 noon, and 6 pm every day, the chickens should not be dehydrated. The chickens begin to receive light (sunlight or light) at around 8 in the morning; around 12 noon is the peak time for laying eggs, and more water is consumed in the body; around 6 in the afternoon, the lighting time is about to end, and the chickens begin to prepare for night rest , Let the chicken drink enough water to prepare the body for consumption at night. In addition, it should be noted that in winter, the weather is cold and the temperature is low. It is best to drink warm water to the chicken to reduce the body heat loss of the chicken and enhance the cold resistance ability,...

.jpg)

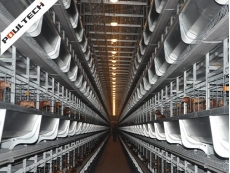

This layer farm project is established in Luoyang city, to reach the target capacity of 1,000,000 layers, this new layer house has been founded, it’s the No. 4 layer house in this project, equipped with our 6 rows 9 tiers TechPro layer cage equipment, raising 120,000 layers in this house, make this project reach a total capacity of 340,000 layers. This new layer house size is 100x18x9 meters, it’s steel structure construction, made according to our design, with panels covering the purlins and beams of the roof, this design benefits the ventilation and cooling system for this project. This 9 tiers layer cage equipment is 3+3+3 structure, and there are platforms between 3&4 tier cage, and 6&7 tier cage, this design can fully use the land source, and convenient for operating the above cage systems.

Nebraska Public Media published an article that the chicken manure discharged from the chicken houses polluted the nearby water source. It’s very simple to solve this problem. Let’s look at our chicken manure air drying project in Guizhou Province, China. Manure Drying Machine using the wind and heat blow out by fans to dry the manure for further production. The moisture content in fresh chicken manure can be reduced to about 20% within 48 hours. Through the air drying process, it can block the odor generated by the fresh feces during the fermentation process, the breeding of pests and diseases, and other damage to the environment and personnel. Dried chicken manure is suitable for long-term storage to various fertilization seasons and significantly reduces transportation and storage costs.

TechPro layer cage includes special cage, fully automatic drinking water equipment, feeding tower, automatic feeding device, automatic feeding system, fully automatic control electrical equipment, fully automatic egg gathering machinery, poultry house environment control system, fully automatic ventilation equipment, wet curtain evaporation cooling equipment, automatic conveyor type fecal cleaning equipment and automatic control integrated system. The farm must be equipped with an emergency generator set, which can be switched automatically in time. Ensure that the light in the shed is uniform, and the egg conveying system, manure cleaning system, feeding and feeding systems are used normally. The automatic feeding system compose with feed carts, auger pipes, feed silo, feed trough and feed adjustment apparatus. The drinking system is consisting of PVC material square shape pipe, nipple drinkers, which is made of plastic and stainless steel in red color, in each section and the bottom plastic drop catcher in V shape. Chicken manure fell on the manure belt Under the cage in each tier then transports to the horizontal manure conveyor.After first cleaning, we have added the second scraper device, it’s making the manure belt very clean. The second manure scraper designed in adjustable way according to chicken manure thick degree....