On 14th March, our old friend from Nepal visit our factory. Our friend start to use our layer cage system from last year, this is the first time he visit our factory, he was surprised by the scale of our new factory, satisfied with the quality of our products and, of course, our thoughtful service. On March 15th, we talk about the business. On 20th March, We sign more cooperation orders. We will use better products and services to add bricks to the poultry business of our new and old friends.

On November 17, 2022, POUL TECH's new factory is basically completed!The layout of the plant had been planned since October 2020. A planning map needed to be beautiful and practical.

Welcomes to HENAN POUL TECH MACHINERY CO., LTD., Here we are briefly explaining the layer poultry Farming. Layer poultry farming means raising egg laying poultry birds for the purpose of commercial egg productions. Layer chickens are such a special species of hens, which need to be raised from when they are one day old. They start laying eggs commercially from 18-19 weeks of age. They remain laying eggs continuously till their 72-78 weeks of age. They can produce about one kg of eggs by consuming about 2.25 kg of food during their egg laying period. For the purpose of producing hybrid eggs layer, consider the various characteristics of cock and hen before breeding. There are various types of highly egg productive layer breeds available throughout the world. According to the nature and color of egg, two types Layer Breeds are White Egg Laying Hens and Brown Egg Laying Hens. The Brown egg laying hens are relatively larger in size. They eat more foods, compared to white egg layers. Lay bigger eggs than other laying breeds. Egg shell is brown colored. There are many types of brown layer available. Among those Isa Brown, Hi Sex Brown, Sever 579, Lehman Brown, Hi...

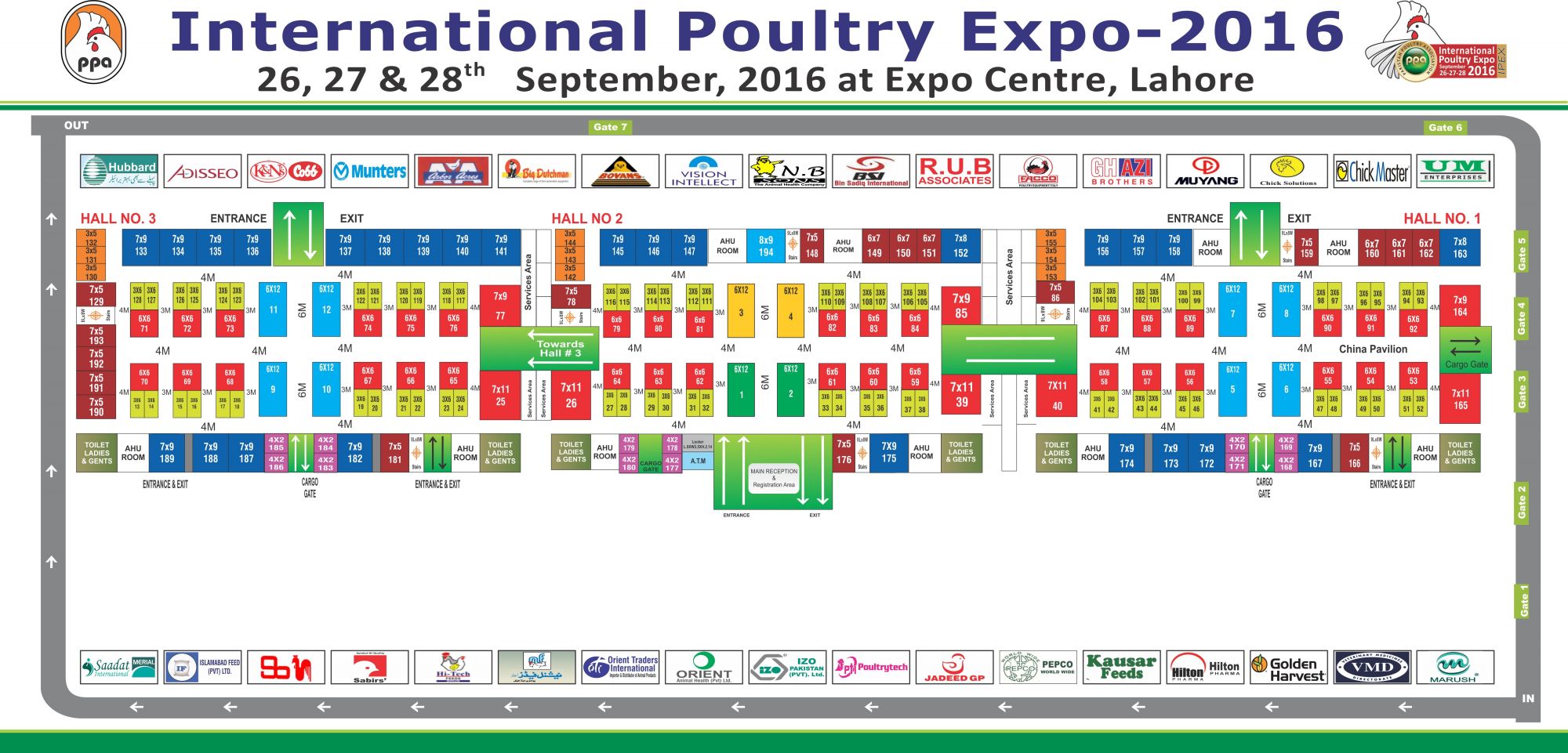

Henan Poul Tech Machinery Co., Ltd. Attend to IPEX Pakistan 2016 IPEX Pakistan 2016 was hold in 9.26—9.28 in Lahore, the third city in Pakistan. In the invited of customers , our company attend to it. Pakistan is the world’s 25th largest economy which has a diversified economy. As a fast-growing developing country, by 2015, Pakistan’s average annual economic growth lasted 4 years to 7%. Nevertheless, Pakistan is still a developing country. Agriculture is the country’s pillar industry, the country’s 26% of GDP is from agriculture and 44% of the labor force engaged in agriculture, labor costs, transportation costs are relatively low, while the domestic population of 200 million people in the consumer market. Pakistan has relatively complete investment regulations to protect foreign investors, especially in agriculture and animal husbandry. It gets the government’s strong supporting. Raw materials for the import of zero tariffs are not locally produced for the import of agricultural machinery. Good market potential and the strong support of the government make Pakistan has become a businessmen competing to open up the international market. Pakistan is China’s best strategic partner in Central Asia, and the two countries have in-depth cooperation in various fields. And Pakistan has...

1. Chicken house: built by local steel structure company in France, chicken house construction engineering quality is very high, the domestic rare, all the chicken house and peripheral facilities of life are all steel structure, two ear wall each have six (after the former three parts, the upper three), a total of 12 cross wind window opening and closing device, under the eaves to cover one side wall, will the device be covered, only 12 operating window on the outer wall of the ear wall. 2. Internal: using 4 + 4=8 layer design, pedal to production for hot dip galvanized steel plate welding, very strong. Cross wind window in two ear, the wall surface, automatic opening and closing: after the former paragraphs have induction temperature difference and pressure difference sensor, lateral wind window can adjust the Angle of opening and closing automatically according to the data change, ensure the ventilation effect. 3. The front and back side up and leave a door unlocked, a total of four, for chicken layer cage and elimination of the chicken, each chicken house laying 63000birds,they need 20 people in five days of work to complete the laying and elimination chickens.POUL TECH at the invitation of the...

From September 13th to 15th , 2019, POUL TECH participated in the most professional animal husbandry industry exhibition in Pakistan – IPEX. Our company brought excellent cage equipment to the exhibition. Meet with 5,000 enterprises and friends of poultry farms from many countries. The exhibition is held at the Lahore city, Pakistan. It is held annually by the Pakistan Poultry Association. More than 5,000 enterprises from Argentina, China, France, Germany, Indonesia, Kyrgyzstan, Malaysia, Ireland, Russia, Turkey, and the United Kingdom, as well as more than 10,000 spectators and media people attended the exhibition. This exhibition will bring the latest relevant industry information and the most cutting-edge industrial technology and provide a professional international trade platform for industry exhibitors and poultry farms friends. POUL TECH has talked with more than 100 farm customers and reached cooperation intentions with some customers. Our cage sample get the praise from many customers and the cage brochure also were all sent out. In this exhibition, our company not only advertise our cage equipment, but also learned more advanced technologies on poultry equipment.